Portable Straw Crusher

Portable Straw Crusher

The Portable Straw/Grass/Corn Stalk Crusher/Shredder is applied to process garden waste. It can crush wasted branches, shrubs, bamboo, straw, etc. It is widely used in gardening, agriculture, urban greening, and biomass energy. It can effectively solve garden waste, promote resource recycling.

READ MORE + Corn Sheller Thresher

Corn Sheller Thresher

Corn threshers thresh dried corn ears. Most are axial-flow drum-type, but some are vertical threshing disc-type. They have been popular with farmers for years due to their high production efficiency, excellent threshing quality, ease of operation, simple structure, durability, reliability, and convenient maintenance.

READ MORE + Maize Grinder

Maize Grinder

The corn flour mill is an upgraded version of the small drum flour mill. This machine can grind grains such as wheat, sorghum and corn into flour. Due to the use of a high-pressure blower and a small storage tank with two hoppers, the machine is fully automatic.

READ MORE + Vegetable Chopping Machine

Vegetable Chopping Machine

The vertical vegetable cutter is composed of a knife disc, a housing and a frame (as shown in the figure). At the top of the knife disc, there are 8 movable knives (4 large pointed knives and 4 small pointed knives) and 2 scraper plates. On the cylindrical surface, there are 8 fixed knives (small pointed knives).

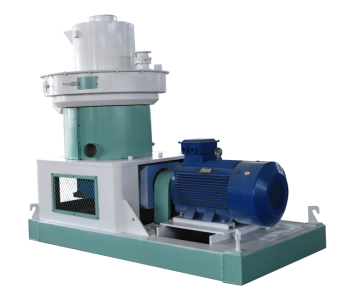

READ MORE + Vertical Ring Die Pellet Machine

Vertical Ring Die Pellet Machine

The vertical ring die pellet machine has a strong pressure and is suitable for pressing materials that are difficult to bond. Vertical ring die pellet machine is widely used in power station, wood factory, feed factory, chemical factory, becoming the ideal equipment for compression density molding with small investment, fast return and no risk. Pellet making machine can handle various materials: agricultural waste (coconut shell, palm shell, wood log & branches, sugarcane bagasse, rice husk, pine wood, etc.), residues of various kinds of wood as branches and trunks, the peels and other raw materials of various crops.

READ MORE + Flat Die Pellet Mill

Flat Die Pellet Mill

Flat Die Pellet Mill has two types of working principles: one is the type in which roller rotates and the other one is the type in which die rotates. According to the power supply, there are 4 types of flat die pellet mills: electric pellet mill, diesel pellet mill, PTO pellet mill and gasoline pellet mill. Depending on the usage of pellets, flat die pellet mill can be divided into biomass pellet machine and animal feed pellet machine. The core components are composed of a rotating flat die and a fixed roller.

READ MORE + Feed Pellet Machine

Feed Pellet Machine

Feed pellet machine (also known as pellet feed machine or pellet feed forming machine) is widely used by farmers who breed chicken, rabbit, cow, sheep, cattle, pig, and animal husbandry. The feed pellet machine adopts a template, and the pressure roller is made of alloy steel after special treatment,so the nutrients inside the raw materials can be maintained. The length of the particles can be controlled by adjusting the cutting angle.

READ MORE + Forage Grass Crusher

Forage Grass Crusher

Grass crusher machines are mainly used to cut crop straw and forage grass, because most of the cuts are roughage, suitable for cattle, sheep and other livestock farmers. Generally speaking, grass crushers are divided into two types: motor and diesel engine trailer, and can also be equipped with gasoline engine and diesel engine. They can be apply to cut all kinds of wet and dry crops, corn stalk, rice straw, wheat straw, bean stalk, bean stalk, green grasses, sorghum stalk with big capacity. It is suitable agricultural equipment for cattle, farm, farmer which is feeding cow, horse, sheep, deer, rabbit and others.

READ MORE + Rotary Dryer Machine

Rotary Dryer Machine

Drum dryer machine is the main body slightly tilted and can be in a specific range of adjustable rotational speed of the cylinder, the wet material is fed into the cylinder by the feeding machine, the cylinder is evenly distributed in the cylinder under the turnover of the platen, the material is evenly distributed in the dryer and dispersed and through the cylinder through the full contact of hot air (concurrent or countercurrent) to accelerate the drying of the heat transfer, mass transfer, so as to achieve the purpose of drying.

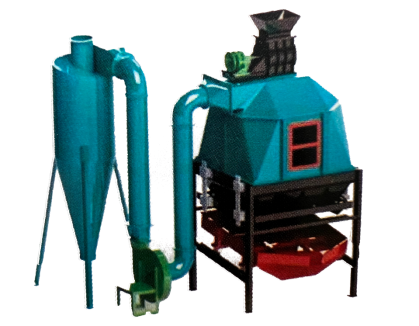

READ MORE + Pellet Cooler

Pellet Cooler

The cooler is mainly used for cooling of hot pellet feed, about 3-5 degress higher than room temperature, which is in the feed pelleting section.

READ MORE + Wood/Tree Branch Crusher

Wood/Tree Branch Crusher

The tree branch crusher/shredder is applied to process garden waste. It can crush wasted branches, shrubs, bamboo, straw, etc. It is widely used in gardening, agriculture, urban greening, and biomass energy. It can effectively solve garden waste, promote resource recycling.

READ MORE + Horizontal Wood Crusher

Horizontal Wood Crusher

The horizontal crusher is expert in making woods into wood chips.It can be driven by a diesel engine or an electric motor, its high speed rotating blades are capable of crushing wood of various hardness and density,and the hydraulic forced-feed system facilitates reduced bulk and fast feeding of fluffy branches.The front pressure roller can prevent the material from flowing back.So it can efficiently process logs, trees, straw, wood pallets, waste wood and other organic materials into valuable end products.

READ MORE + Wood Shredder

Wood Shredder

Saw-dust making machines are devices powered by electric or internal combustion engines that are used to shred wood chips such as branches and cut them into chips. They are suitable for rough wood, branches, sawdust and other waste wood and can be processed into sawdust at one-time. The finished wood products are uniform in size and have less impurities. The size of the finished products can be adjusted according to the size of the built-in screen mesh and is suitable for a variety of materials. These chips can be used as compost, mulch or disposed of at recycling centers and later used in other industries such as the furniture and construction sectors.

READ MORE + High-Efficiency Wood Crusher

High-Efficiency Wood Crusher

The high-efficiency wood crusher is a high-speed machine that uses a sharp blade on one side and an impact blade on the other side, so that the material to be pulverized is sheared by the high-speed blade. The machine can also use blades of various shapes and sizes according to different materials, and the particle size can be obtained by changing the mesh or adjusting the speed.

READ MORE + Hammer Sawdust Making Machine

Hammer Sawdust Making Machine

Multi-purpose hammer saw-dust making machine is an essential equipment for the early production of many industries, especially the pharmaceutical, feed, food, coating and chemical industries. It has wide versatility, can adjust the crushing fineness, has the advantages of high production efficiency, low energy consumption, safe use and convenient maintenance, so it has been favored by all walks of life.

READ MORE + Disc Wood Chipper

Disc Wood Chipper

Disc wood chipper is a special equipment for making high quality wood chips. It is not only able to cut log, small diameter wood and others into high-quality industrial wood chip which has the same length, the neat incision and the uniform thickness, but also can cut lamina, plank and others. So it is suitable for paper mill, particleboard factory, fiberboard factory and wood chip production base. It is the necessary wood processing equipment for small and medium-sized enterprises and individual household.

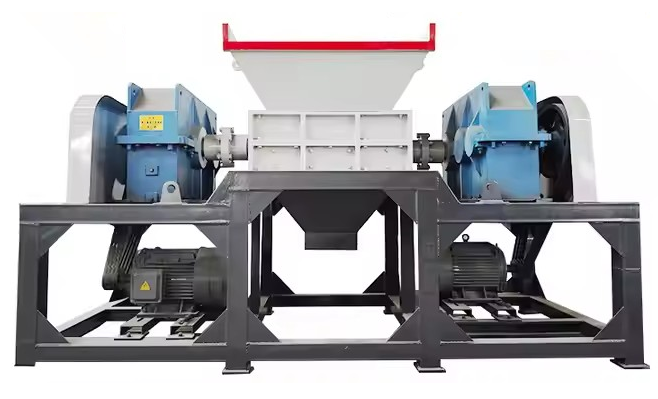

READ MORE + Double Shaft Shredder

Double Shaft Shredder

The double shaft shredder can generally be used to shred solid materials such as plastic, rubber, fibers, paper, wood, electrical components, cables... that are difficult to break, such as nozzle materials, rubber heads, PET bottles, cardboard, circuit boards, wood, plastic barrels, etc. As long as the material is difficult to pulverize, the product that enters the shredder becomes granular.

READ MORE + Mini Wood Log & Branches Shredder

Mini Wood Log & Branches Shredder

Small wood shredder machine is suitable for orchard, wood, forestry, highway tree maintenance, municipal, nursery, and other departments. It is mainly used for crushing various branches cut from pruning trees. After crushing, it can be used as mulch, organic fertilizer, edible fungi, biomass power generation, which can also be used in the production of high density board, particle board, paper industry, the size of the finished products can be adjusted according to the size of the built-in screen mesh and is suitable for a variety of materials. These chips can be used as compost, mulch or disposed of at recycling centers and later used in other industries such as the furniture and construction sectors.

READ MORE + Tub Straw Grinder

Tub Straw Grinder

The tub grinder is a multifunctional crushing equipment, which can crush all kinds of large materials (large diameter wood, tree roots, various weeds). It adopts direct drive mode with strong power, which can effectively and safely convert biomass into debris, which can be used as biomass energy. The equipment adopts a multi-knife rotor cutter roller, the crushed materials are more thorough and reasonable, and the use of advanced materials increases the service life of the blades and reduces the production cost. The disc type root crusher has a high degree of automation.

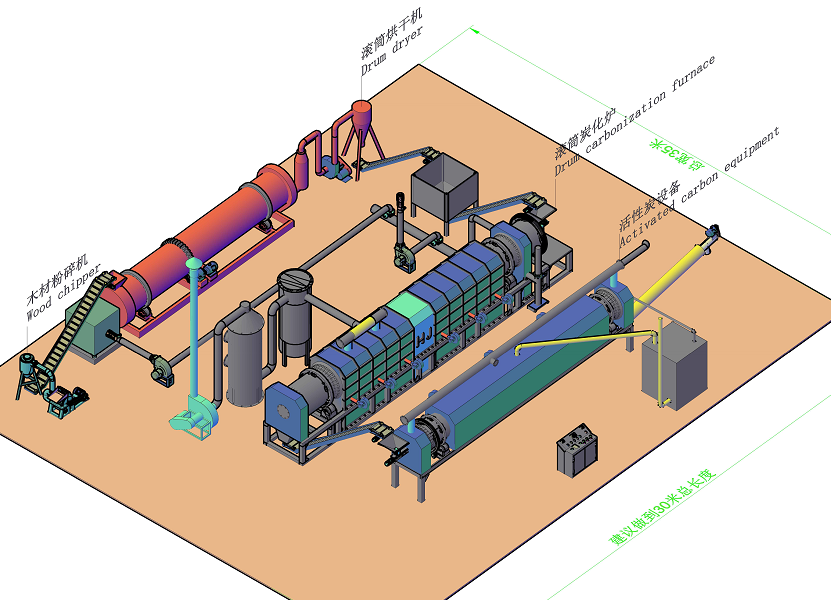

READ MORE + Activated carbon equipment of production line

Activated carbon equipment of production line

Activated carbon is a porous solid carbon with a large specific surface area and strong adsorption capacity! It possesses many characteristics that other types of carbon materials do not have, such as thermal stability, chemical inertness, thermal process ability and pore structure.

READ MORE + Wheel Grinder

Wheel Grinder

Wheel grinder mixer is mainly composed of the grinding wheel, grinding disk, and so on. The height of wheel can be automatically adjusted, when have a large or hard material, the rolling wheel can automatically rise, over the hard material, due to its own gravity and automatically fall.

READ MORE + Hammer Mill

Hammer Mill

Wood hammer crusher is widely used to crush small-sized materials with a diameter of no more than 50mm, such as branches, wood chips, cotton stalks, corn stalks, wheat straw, etc. Wood hammer mill is a kind of wood crusher. Wood crusher is a machine that crushes large-sized raw materials into powder.

READ MORE + Continuous Drum Carbonization Furnace

Continuous Drum Carbonization Furnace

The continuous drum carbonization furnace produces solid charcoal, combustible gas, wood vinegar and tar by anaerobic pyrolysis and carbonization of waste biomass such as straw, rice husk, wood, bamboo, fruit shell, coconut shell, palm shell and garbage, sludge, animal feces and other materials under high temperature conditions in the furnace, thereby maximizing the utilization of resources and having high economic and environmental benefits.

READ MORE + Vertical Carbonization Furnace

Vertical Carbonization Furnace

The vertical carbonization furnace is made of high temperature material by using high-tech environmental purification technology, which is durable without oxidation or deformation.

READ MORE + Horizontal carbonation Furnace

Horizontal carbonation Furnace

The horizontal carbonation furnace controls the temperature, time and environmental atmosphere in the carbonation chamber, and releases the moisture and volatile substances in the raw materials through a series of chemical reactions to form a stable charcoal product.

READ MORE + Rotary Dryer

Rotary Dryer

The self-made combustible gas is used as the heating source, and the drying is divided into two parts: the drum part and the serpentine tube part. The drum part has two layers: the inner drum and the outer insulation.

READ MORE + Air Flow Dryer

Air Flow Dryer

This dryer is suitable for drying materials with 30-60% moisture. The wet materials are input into the hopper. The dryer is equipped with two fuel boilers, inlet, steel pipe, exhaust blower (fan), airlock and cyclone separator. The wet materials are input into the hopper. Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Molding Machine

READ MORE + Charcoal Extruder Machine

Charcoal Extruder Machine

This charcoal extruder uses the screw extrusion principle to press charcoal powder, coal powder and other materials (chemical materials, refractory materials, cement materials, iron ore, copper or other materials) into a rod-shaped block (round, rectangular, hexagonal, plum blossom, triangle, etc.) with a certain density and with or without holes in the middle.

READ MORE + Mechanical Charcoal Machine

Mechanical Charcoal Machine

Mechanical charcoal machines use sawdust, tree branches, rice husks, bamboo chips, peanut skins, sunflower seed shells, furfural residue, wine residue, sugarcane bagasse, corn cobs, coconut shells, coffee husks, and crop straw from both northern and southern China as raw materials. After being crushed, they are plasticized at high temperature and high pressure in a molding machine to form semi-finished charcoal. This is then carbonized in a carbonization furnace to create finished charcoal.

READ MORE + Rice Husk/Biomass/Wood Carbonization Furnace

Rice Husk/Biomass/Wood Carbonization Furnace

Rice Husk/Biomass/Wood carbonization furnace is special used for log, wood, jute stick and other long rod-type biomass characteristics, adopts horizontal structure, cart entry and exit raw materials and the advanced hot gas dry carbonization process technology, using a unique carbonization flue gas (volatile hydrogen material and tar, etc.)Back Burning Technology, make full use of the flue gas produced by carbonization process, meet the thermal needs of carbonization furnace itself, greatly increase the carbonization rate, the carbonization rate increased from 80% to more than 95%, and easy to operate, safety and environmental protection, high production efficiency, can save a lot of energy, is the ideal equipment for carbonizing the long rod type biomass materials.

READ MORE + Biomass Fuel Briquettes Machine

Biomass Fuel Briquettes Machine

The equipment adopts the reducer transmission mode, which avoids the belt loss of traditional equipment, power loss caused by the loss of pulleys, pulley maintenance and other problems; the reducer transmission mode has lower main motor power and greater torque. The output is more stable, the output is more stable, the maintenance is easier, the whole machine is overload protected, it is safe and labor-saving to use, and it is more energy-saving to use, achieving low energy consumption and high output.

READ MORE + Solid Waste Disposal Machine

Solid Waste Disposal Machine

This double shaft shredder for garbage is widely used in waste plastics, waste rubber, wood and other bulky waste. The double shaft shredder have been improved, researched and developed with mature technology and advanced design based on more than 30 years of experience in manufacturing such equipment in Europe and America, and improving according to the actual situation in China, which is the reliable equipment for crushing and recycling of waste in China.

READ MORE + Cyclone Dust Collector

Cyclone Dust Collector

Cyclone dust collector The cyclone dust collector, also known as the cyclone separator, is composed of an air inlet pipe, an exhaust pipe, a cylinder, a cone and an ash discharge valve. It has been widely used to separate solid and liquid pellets from airflow, or to separate solid pellets from liquid. It is suitable for the removal of non-sticky and non-fibrous dust, mostly used to remove pellets larger than 5μm.Therefore, it belongs to a medium-efficiency dust collector and can be used for the purification of high-temperature flue gas. It is a widely used dust collector and can be used for boiler flue gas dust removal, multi-stage dust removal and pre-dust removal.

READ MORE + Belt Conveyor

Belt Conveyor

Application range of sidewall cleaned belt convey or Food, metallurgy, coal, mine, dock, environmental protection, grain, chemical industry, building materials, water and electricity.

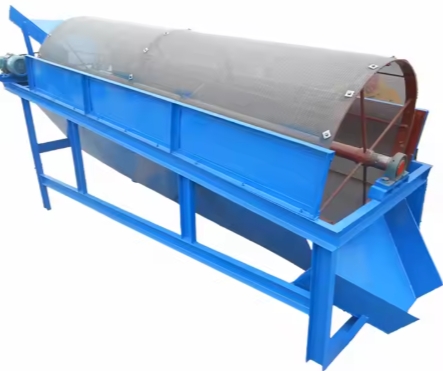

READ MORE + Shaft-Less Drum Screen

Shaft-Less Drum Screen

The shaft-less drum screen is mainly used for grading the pellet size of materials and is widely used in power, mining, metallurgy, building materials, chemical industry and other production industries. It is often used for grading refractory materials, coal, fertilizer, sand field stones, and screening of sticky and wet materials such as coal, coke, lime, gold ore...in order to make the product structure more uniform to meet production needs. The maximum size of the screened product is 100mm, the middle size is 10-50mm, and the finest size can reach less than 3mm.

READ MORE +