We fully devote ourselves to developing green energy equipment & serving our clients with the BEST customized biomass projects & turnkey solutions! And now we are growing as a well-renowned biomass equipment supplier worldwide and the market expansion of our products to YOU!

Saw-dust making machines are devices powered by electric or internal combustion engines that are used to shred wood chips such as branches and cut them into chips. They are suitable for rough wood, branches, sawdust and other waste wood and can be processed into sawdust at one-time. The finished wood products are uniform in size and have less impurities. The size of the finished products can be adjusted according to the size of the built-in screen mesh and is suitable for a variety of materials. These chips can be used as compost, mulch or disposed of at recycling centers and later used in other industries such as the furniture and construction sectors.

The high-efficiency wood crusher is a high-speed machine that uses a sharp blade on one side and an impact blade on the other side, so that the material to be pulverized is sheared by the high-speed blade. The machine can also use blades of various shapes and sizes according to different materials, and the particle size can be obtained by changing the mesh or adjusting the speed.

The horizontal crusher is expert in making woods into wood chips.It can be driven by a diesel engine or an electric motor, its high speed rotating blades are capable of crushing wood of various hardness and density,and the hydraulic forced-feed system facilitates reduced bulk and fast feeding of fluffy branches.The front pressure roller can prevent the material from flowing back.So it can efficiently process logs, trees, straw, wood pallets, waste wood and other organic materials into valuable end products.

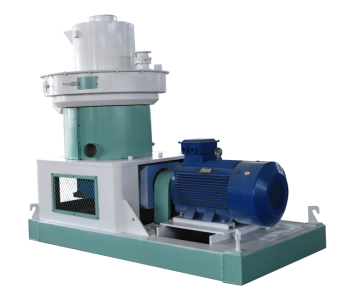

The vertical ring die pellet machine has a strong pressure and is suitable for pressing materials that are difficult to bond. Vertical ring die pellet machine is widely used in power station, wood factory, feed factory, chemical factory, becoming the ideal equipment for compression density molding with small investment, fast return and no risk. Pellet making machine can handle various materials: agricultural waste (coconut shell, palm shell, wood log & branches, sugarcane bagasse, rice husk, pine wood, etc.), residues of various kinds of wood as branches and trunks, the peels and other raw materials of various crops.

Feed pellet machine (also known as pellet feed machine or pellet feed forming machine) is widely used by farmers who breed chicken, rabbit, cow, sheep, cattle, pig, and animal husbandry. The feed pellet machine adopts a template, and the pressure roller is made of alloy steel after special treatment,so the nutrients inside the raw materials can be maintained. The length of the particles can be controlled by adjusting the cutting angle.

Grass crusher machines are mainly used to cut crop straw and forage grass, because most of the cuts are roughage, suitable for cattle, sheep and other livestock farmers. Generally speaking, grass crushers are divided into two types: motor and diesel engine trailer, and can also be equipped with gasoline engine and diesel engine. They can be apply to cut all kinds of wet and dry crops, corn stalk, rice straw, wheat straw, bean stalk, bean stalk, green grasses, sorghum stalk with big capacity. It is suitable agricultural equipment for cattle, farm, farmer which is feeding cow, horse, sheep, deer, rabbit and others.

Mechanical charcoal machines use sawdust, tree branches, rice husks, bamboo chips, peanut skins, sunflower seed shells, furfural residue, wine residue, sugarcane bagasse, corn cobs, coconut shells, coffee husks, and crop straw from both northern and southern China as raw materials. After being crushed, they are plasticized at high temperature and high pressure in a molding machine to form semi-finished charcoal. This is then carbonized in a carbonization furnace to create finished charcoal.

This double shaft shredder for garbage is widely used in waste plastics, waste rubber, wood and other bulky waste. The double shaft shredder have been improved, researched and developed with mature technology and advanced design based on more than 30 years of experience in manufacturing such equipment in Europe and America, and improving according to the actual situation in China, which is the reliable equipment for crushing and recycling of waste in China.

BELET MACHINERY & EQUIPMENT, established in october 2002, dedicated to the improvement and upgrading of biomass technologies, provide consulting, equipment selection, design drawings, equipment manufacturing and installation, equipment maintenance, and professional services throughout the process.

We provide consulting, equipment selection, design drawings, equipment manufacturing and installation, equipment maintenance, and professional services throughout the process. With the mechanical processing equipment, our factory has the ability of manufacturing, processing, cutting, forming, processing, welding, painting, installation and debugging.

Processing Equipment

Processing Equipment

Workshop

Workshop

Spare Parts

Spare Parts  Warehouse

Warehouse Equipment Packaging

Equipment Packaging Biomass pellet is a small, cylindrical, and condensed form of organic material derived from various renewable sources. These pellets serve as a viable and sustainable alternative to traditional fossil fuels and play a significant role in addressing energy and environmental challenges.

Biomass pellets are typically produced from a variety of organic materials, including

wood, agricultural residues, energy crops, and even some types of waste.