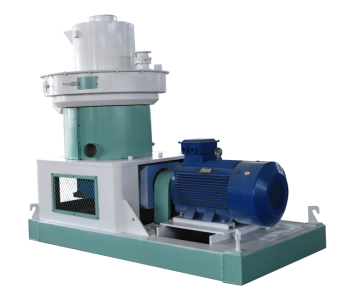

Charcoal Extruder Machine

Charcoal extruder machine is a charcoal forming equipment that uses the principle of screw extrusion to c

Application

Wood, rice husk, peanut shell, straw and other carbon containing wood material (without any additives) can be made into solid fuels under the condition of high pressure and high temperature. The kind of machine can crush the particulate waste materials (length≦5mm, diameter≤3mm) the water content<12% of bamboo, wood, husk, straw (except rice straw, wheat straw) into solid hollow rods without any binders under the high temperature and high pressure.

It is widely used in the molding of coal powder, lignite, anthracite, iron powder, aluminum powder and other raw materials. The specifications and shapes of the finished rod can be: hollow hexagonal, square, hexagonal plum blossom, hollow round rod, multi-strand finger rod, particle, bar, hollow hexagonal, etc.

Wide application in many scenarios.

Burning Effect