What Is Hay Cutter?

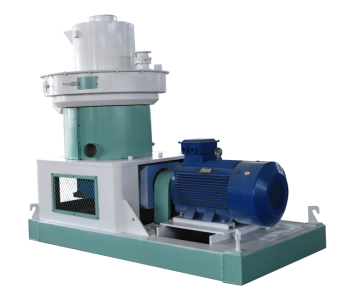

Hay cutter and silk kneading machine is a new type of straw processing machine integrating hay cutting, crushing and kneading.

Kneading can turn crops and weeds such as corn straw, bean straw and wheat straw into soft filamentous feed for cattle and sheep.

It can also be pressed into pellets with pellet feed machine and briquetting machine to facilitate storage and transportation. It can be used as hay cutter, pulverize and beater alone.Through the interaction of blade, hammer and kneading plate, the coarse and hard dry scale is processed into fine wires without hard knots, so as to achieve the purpose of fine processing; This machine can cut corn straw scale, yellow bamboo grass, sugarcane head, rice straw, bean straw, peanut seedling and other dry and wet grass. It has a wide range of application. It is an ideal equipment for raising cattle, horses, deer, pigs, rabbits and other large and medium-sized farms and families to raise poultry and feed!

When the hay cutter is in operation, all safety protection equipment must be complete.Operators must fully understand the machine's performance. It is strictly prohibited to start the machine when drunk, ill, or overly fatigued. During operation, people and objects must not approach the rotating parts. Teenagers under the age of 16 and those who have not mastered the machine's operation rules are not allowed to work alone.The working area of the hay cutter should be spacious, and fire-fighting equipment should be available.

When feeding hay, the operator should stand on the side of the feeding hopper. It is strictly prohibited to put both hands into the guard cover of the feeding hopper. At the same time, it is necessary to strictly prevent wooden sticks, metal objects, bricks, and stones from entering the machine to avoid damaging the machine and injuring people.The cutter disc must not be reversed.The hay cutter must operate at the specified speed. It is strictly prohibited to operate at excessive speed or overload.